Toll Free: 1800 3000 6650

- Walplast

- About Us

About Us

Walplast at a Glance

Walplast is India’s leading and major manufacturer of building materials company, known for its hassle free, home-building solutions. Unique products tailor-made for Indian climatic conditions, sustainable operations and initiatives that advance the company’s philosophy of contributing to the larger benefit and welfare of society, have made it the most reliable building materials brand in India.

Walplast Products Pvt. Ltd, subsidiary of DryChem India Private Ltd. is an Indian Multinational Corporation founded by visionary Mr Ashok Mehta in 2004. It is one of the largest, most reputable and most well-known producers of building materials and the 3rd largest manufacturer of Wall Putty in India.

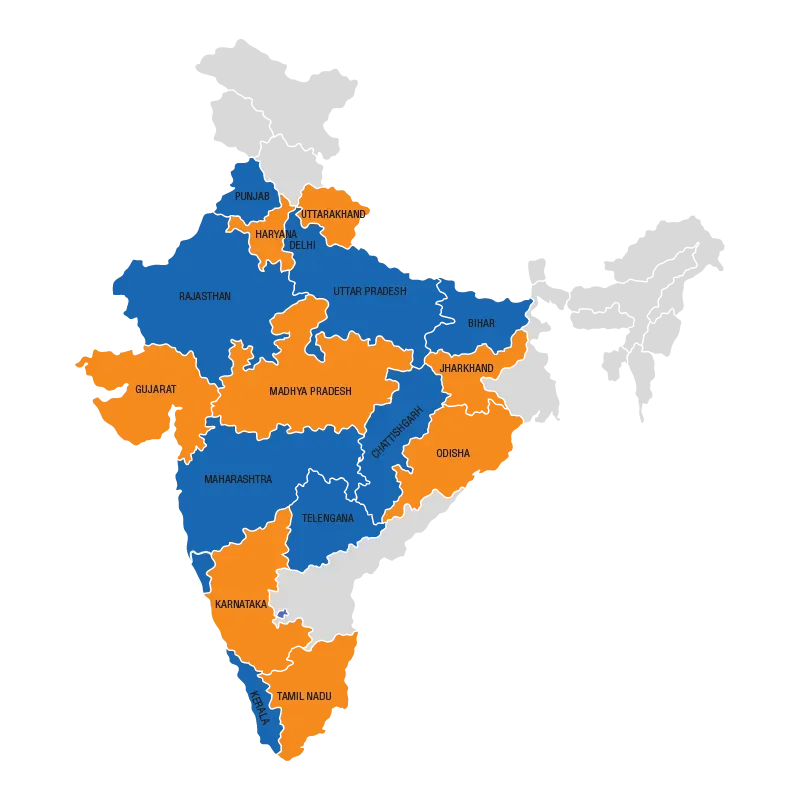

Walplast has 25 manufacturing facilities judiciously and tactically built across various parts of the nation. It is also equipped with NABL-accredited state-of-the-art R&D Labs that are fully equipped with groundbreaking, cutting-edge testing equipments conforming to international standards and criteria. Globally, Walplast exports to more than 14 countries across GCC region & North & Central Africa. It is one of the largest exporters of Wall Putty from India.

Our B2C interface Homesure is a recognized and preferred brand within construction ecosystem that delivers superlative customer experience on product performance, solutions and services. We help create robust, reliable and sustainable communities, with a network of 800+ active Distributors, 6000 + Dealers & more than 65000+ influencers engaged in our business operation. Additionally, direct employment to over 1000 employees.

Our HomeSure product range includes HomeSure Wall Putty, TileEx Tile Adhesives, GypEx Gypsum based products, w-Shield waterproofing chemicals, Admixtures, Mastertouch decorative paints and other building materials with a growing business portfolio.

Whatever Walplast desires and intends to do, is for the value addition of its customers. It believes that its source of sustenance is customers. It derives immense satisfaction from the benefits of its clientele. With these firm convictions and strong beliefs together with a plethora of excellent products on offer, the company is bound to go great guns and radically transform the construction industry itself. Its dream to be the most credible and dependable organization of the nation and a formidable force in the international construction industry has already been achieved. Walplast has dedicated itself to implementing its master plan which blends industrial excellence with efficiency, recognition of employees’ contributions, regional customs and cultures, and protection of ecology and natural resources while strictly abiding by their policies.

Milestones

Board of Directors

Leadership Team

Nirav Mehta

Sr. Vice President – IT, SCM, Exports, Commercials & Business Head – Imports & Miraj

Full Profile

Nirav Mehta

Sr. Vice President – IT, SCM, Exports, Commercials & Business Head – Imports & Miraj

Full Profile

Aniruddha Sinha

Sr. Vice President & Group Marketing, PR, CSR Head & Business Head – P2P Division

Full Profile

Purpose, Vision, Mission

PURPOSE

To accomplish a positive change in the ecosystem through innovative & reliable products, services, solutions and partnership

VISION

To be a brand of choice for the construction ecosystem by delivering superior customer experience and become ₹ 2000 Crore Group by Y2025

MISSION

We will deliver superior customer experience by remaining agile, competitive and responsive to every stated and unstated need of the customer

Core Values

INTEGRITY

Honesty, Reliability, Trustworthiness, Ethical code of conduct. Openness. Responsible to serving communities, partners and customer

COMMITMENT

Reflect on your own habits. Work toward perseverance. Remain resilient. Practice transparent leadership. Provide feedback. Maintain a relational approach. Be your team’s voice. Make team members feel valued. Respond with a sense of urgency to delight your customers

INNOVATION

Generate Out-Of-The-Box solutions. Deliver superior Customer Satisfaction and Value Creation. Intelligent, inclusive and strategic thinking. Solve challenges than simply completing tasks

COLLABORATION

Working together across functional groups, hierarchies, businesses and geographies. Building mutual trust, transparency and teamwork. Leveraging diverse competencies and perspectives for the benefit of synergy while fostering partnership through collaboration

EXCELLENCE

Respect every individual. Lead with humility. Embrace scientific thinking. Focus on process. Assure quality at the source. Seek and deliver value at every step. Think systemically. Create consistency of purpose. Create value for the customer. Continuously and passionately strive to implement solutions and proactively solve challenges.

Research & Development

Walplast’s strong credentials in research, development, and innovation have helped it to create and develop new products and services tailored to the needs of its customers.

At Walplast, we are dedicated to fostering a culture of innovation and continuous improvement, which is why our research and development (R&D) is a crucial component of our strategic vision. As an NABL (National Accreditation Board for Testing and Calibration Laboratories) (Standard no. ISO/IEC 17025:2017) accredited manufacturing company, we are committed to maintaining the highest standards of quality and technical competence in our R&D processes.

We strictly adhere to the requirements set forth by NABL. Our certified state-of-the-art R&D Labs are fully equipped with cutting-edge testing equipments which conforms to international benchmarks and criteria specified by European and American standards for product testing.

A team of qualified professionals, use scientific methods to carry out quality checks & various adhesion tests of the products.

We appreciate the value of knowledgeable staff members and skilled personnel as the driving force behind our R&D projects. To make sure that our team is knowledgeable about the latest and emerging technologies, methodologies and market trends, we invest in continual training, professional development, and collaboration opportunities. The company encourages cross-functional teams to collaborate in order to achieve shared objectives. We encourage a culture of creativity and problem-solving that fuels innovation by utilising the special knowledge and viewpoints of people from many disciplines.

We regularly track and evaluate the performance of our R&D initiatives to ensure that they are delivering the desired outcomes and contributing to our strategic objectives. This includes monitoring key performance indicators (KPIs) and conducting periodic reviews to assess the effectiveness of our R&D efforts.

Walplast emphasizes the importance of continuous improvement as a core principle. We actively seek feedback from customers, employees, and partners to identify areas for further development and optimize our R&D processes.

Our commitment to NABL accreditation standards further reinforces our dedication to technical excellence and quality assurance.

Walplast understands how to comply with the current requirements, without in any way jeopardizing the prospects of future generations. As a result, the organization also ensures to keep a balance and stability between economic upswing and progress, care for the environment and social well-being.

Setting the Quality Benchmark

Walplast is committed to delivering value for all its stakeholders through innovative, top-quality, and superlative products. We offer our loyal customers an array of building and construction solutions that are tough, long-lasting, and unique to the industry. The organization also brings to the table its team’s experience and proficiency in working with building materials for years.

Consistent and unfailing customer satisfaction together with continual improvement is ensured through the effective implementation of the Quality Management System, stringently in compliance with national and International benchmarks.

At Walplast, we understand that success in the building materials industry is derived and put together from a foundation of quality. Our quality objective policy is designed to ensure that our products and services consistently match and quite often surpass the expectations of the clientele, putting in place the yardstick for excellence in our industry.

Our quality objective focuses on the following key areas

We strive to deliver a high level of customer satisfaction by offering products and services that continuously comply with or exceed customer requirements. We regularly assess customer satisfaction through feedback and surveys. The acquired wisdom is utilized to drive continuous improvement.

We are committed to meeting or surpassing all applicable industrial criteria and regulations, steadfastly upholding all authorizations, certifications and accreditations as required, and regularly updating our processes to remain synchronized with industry best practices.

We embrace a culture of continuous improvement, setting specific, measurable, achievable, relevant, and time-bound (SMART) quality objectives and regularly reviewing our progress against these objectives. This helps us to identify areas for improvement, prioritize our efforts, and track our progress.

We invest off and on, in the training and development of our employees, so that they acquire the necessary skills, competence, and expertise to serve as per our commitment to quality and excellence. Our objective is to maintain a highly skilled and motivated workforce that contributes to the success of the business by and large, and the satisfaction of our esteemed customers.

We unceasingly monitor, evaluate, and analyze our processes to identify avenues and opportunities for improvement. Our aim and objective actually mean fine-tuning our processes to enhance efficiency and effectiveness, reduce waste, and minimize errors.

We work hand in hand with suppliers who share our devotion to perfection and excellence and establish clear expectations for their performance. The organization keeps sustaining strong bonds while sharing technical knowledge with the suppliers so that the materials and components they provide consistently meet its stringent quality standards.

We aim to minimize our environmental impact by setting and achieving sustainability objectives, such as reducing waste, conserving resources, and implementing environment-friendly practices throughout our operations.

By setting clear and measurable objectives in these key areas, our quality strategy serves as a roadmap for achieving and maintaining excellence in the building materials industry. As a valued customer, you can trust that the products and services you receive from Walplast will consistently meet your needs and exceed your expectations.

If you have any questions or concerns about our quality process, please do not hesitate to contact us.

Expanding our Reach and Delivering Excellence Globally

At Walplast, we are proud to offer our exceptional products and services not only to our local market but also to customers around the world. Our export process is designed to ensure that we consistently meet the unique needs of our international customers while adhering to all applicable laws and regulations.

Headquartered in Mumbai, the company operates from 17 states in India and is one of the largest exporters of wall putty (Skim coat) from India. In 2010, we took the first step towards building a global presence, when we commenced exporting to the UAE. Thereafter, we started exporting our products to other countries as well. The company holds a commanding position in India and is exporting and marketing its products in countries like UAE, Oman, Nepal, Maldives, Fiji, Kenya, Nigeria, Yemen, Somalia, Tanzania, Mozambique, Rwanda, Jordan, South Africa, Democratic Republic of Congo, Republic of Congo, Philippines, Mauritius, Sri Lanka, Jamaica, Kuwait, Bahrain, etc. We are one of the most favoured manufacturers and exporters of Dry mix products.

We follow the following parameters

We sincerely abide by the set of laws, policies and regulations related to export, including those governing the import and export of goods, services, and technology. This includes acquiring the requisite and obligatory licenses, permits, and certifications to ensure that the goods can be transported legally and smoothly across the borders of different countries.

We conduct prior and in-depth market research to analyze customer requirements in each target export market before launching our brand of goods, enabling us to customize our product offerings and services in compliance with their needs. Our export strategy is guided and steered by a deep understanding of local market dynamics, regulations, and consumer preferences.

We strive to offer competitive pricing for our products in international markets, taking into account factors such as currency fluctuations, import duties, taxes, and shipping costs. Our objective is to provide our valuable customers with outstanding benefits and utility in lieu of their investment.

We engage in stringent quality control practices to ensure that our products either meet or surpass international standards and customer expectations. Our export strategy emphasizes the importance of delivering high-quality products that consistently perform well in diverse environments and conditions.

We collaborate with reputable logistics partners to assure the timely and efficient delivery of our products to customers across the globe. Our export policy is highly concerned with and focussed on ensuring that our products arrive at their destination in perfect condition and according to schedule.

We are committed to providing superlative customer support to our international customers, by responding with timely and accurate communication, proper technical assistance and after-sales services. Our export strategy prioritizes the importance of being responsive to and supportive of our customers’ needs, regardless of their location.

We continuously review and update our export policies to stay aligned with changes in international trade regulations, market conditions, and customer expectations. By proactively adapting to the evolving global landscape, we ensure that our export game plan remains relevant and effective.

- Home Sure brand distributor model.

- Toll Manufacturing B2B.

- Joint enterprise.

- The technology-based business that customizes products to meet customer needs.

Transform Your Walls with Flawless Finesse

Contact

-

CIN: U14106MH2004PTC147149

-

-

-

Plot No. A-246,

TTC Industrial Area, M.I.D.C.,

Mahape, Navi Mumbai – 400 701, Maharashtra, India

© All Copyright 2026 WALPLAST.COM | Terms & Conditions | Privacy Policy | Disclaimer